Heat-Treated Glass

Description

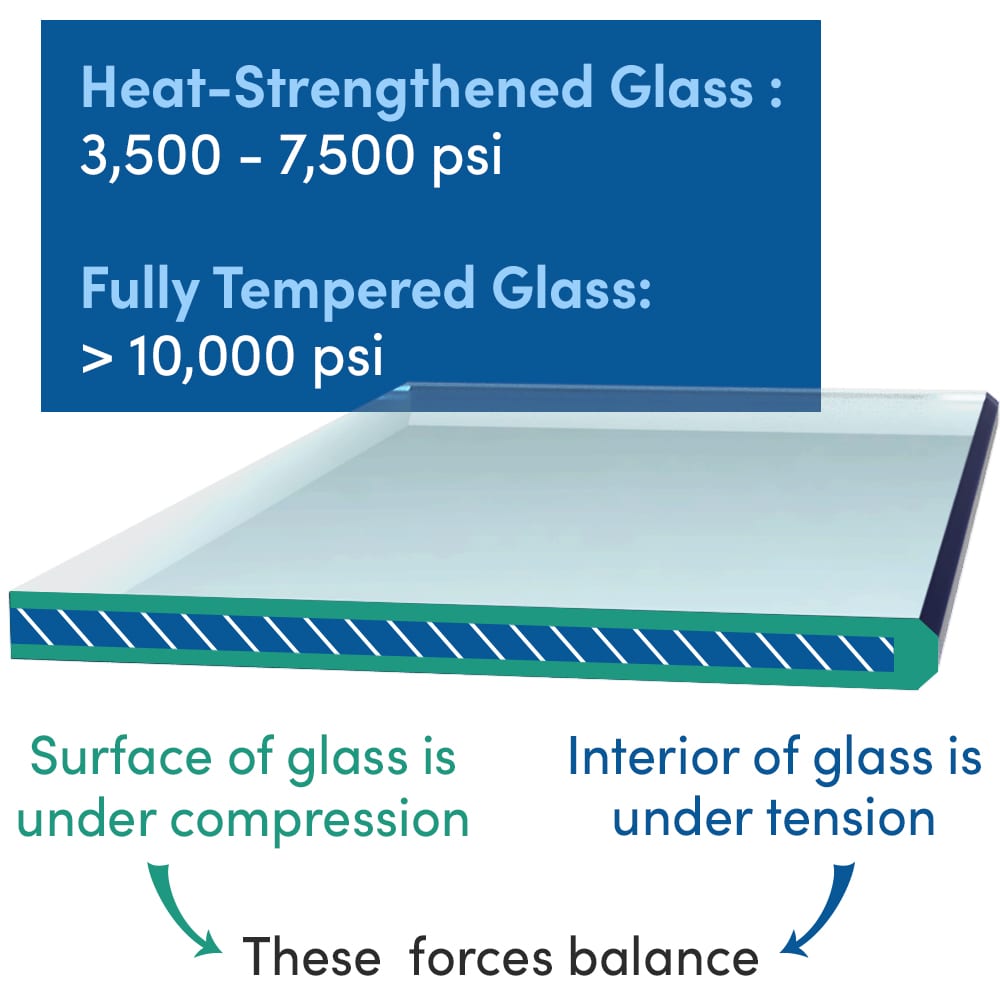

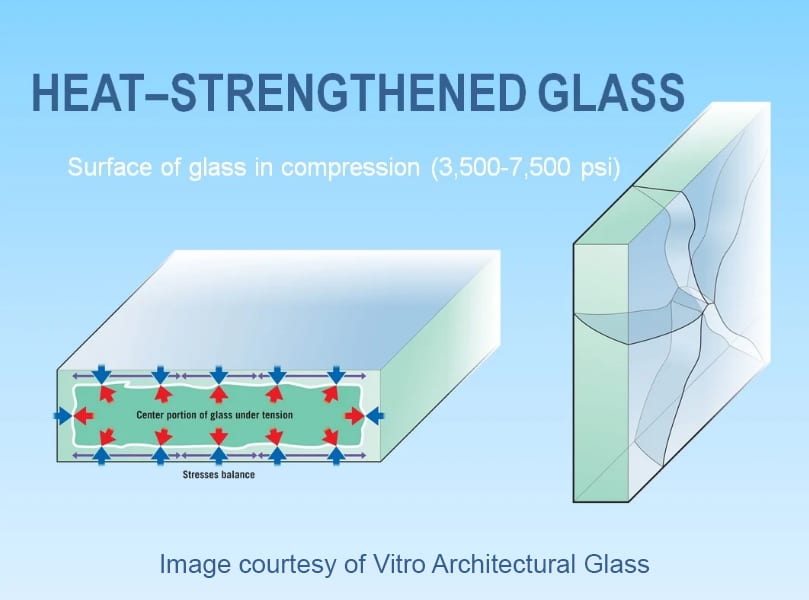

Heat-treated glass is a term used to describe the product that results from introducing Annealed architectural glass into a tempering oven at a temperature of approximately 1,150° F, and then subsequently exposing both sides of the glass to high-pressure cooling or “quenching” conditions that serve to induce permanent zones of glass surface compression. As glass undergoes this procedure, its physical properties are altered where there is a significant increase in residual surface compressive strength and overall resistance to shock and thermal stress.

There are two general categories of heat-treated glass – heat-strengthened glass and fully tempered glass, both of which Hartung produces in strict accordance with the requirements and tolerances outlined in ASTM C1048. Heat-strengthened glass is twice as strong as annealed glass. It is better suited to resisting thermal stresses and edge damage and features a breakage pattern that is more likely to be retained within a glazing frame in case that breakage occurs. Fully tempered glass is four times as strong as annealed glass. It too offers superior resistance against thermal stresses and edge damage, but its breakage pattern is more conducive to having glass fall out of a frame when breakage takes place. Because of that and how fully tempered glass breaks into small, relatively harmless pieces, it is classified by building codes as a suitable option where “Safety Glass” is required.

Why Choose Hartung?

Highest Quality Tempering Furnaces

Hartung employs a fleet of world-class tempering furnaces across the enterprise. Our tempering furnaces give us the ability to produce high-quality heat-treated glass products on a consistent basis.Oversize Capabilities

Our facilities and processes are carefully designed to handle the production of oversized heat-treated glass without compromising quality or durability.Flatter Glass

Optical distortion is an inherent feature associated with heat-treated glass. Through Hartung’s commercial glass facilities, optical distortion is more effectively monitored and controlled. With cutting-edge optical distortion measurement equipment being used as a critical part of our quality control inspection process, Hartung is able to consistently put out optically flatter glass.Fast Glass

We have multiple shifts working around the clock to meet your schedule and your project needs. Ask your local Hartung partner about our expedited lead times for monolithic heat-treated glass products.Key Product Features

Meets Building Code Requirements

Using tempered glass can reduce the probability of serious injury in areas where human impact is probable. It can be used in applications where safety glazing is required by code, and it is widely used in shower doors, building entrances, glass railings and balustrades, vision and spandrel areas, and skylights.Improved Resistance Against Thermal Stress

Using heat-strengthened and tempered glass on your project gives you a building product that is more resilient against exposure to temperature extremes and differential shading conditions.Improved Resistance Against Shock

Where greater impact resistance is necessary, consider using heat-strengthened glass products. For any commercial glazing application, Hartung recommends the use of heat-treated glass.Improved Resistance to Loads

Heat treating glass increases its resistance to wind and snow loads. This improved performance can be critical where glass is used in structurally-glazed applications.

Heat-Treated Glass Gallery

Explore Hartung Products

Bird Friendly Glass

Insulating Glass

Laminated Glass

Laminated Glass

View Detail

Shower Enclosures

Shower Enclosures

View Detail

Entrance Systems

Entrance Systems

View Detail

Railings

Railings

View Detail

Security Glass

Security Glass

View Detail

Printed Glass

Heat-Treated Glass

Heat Treated Glass

View Detail

Heat Soaked Glass

Heat Soaked Glass

View Detail

Case & Sheet Distribution

Interior Solutions

Interior Solutions

View Detail

1-800-552-2227

1-800-552-2227